Bearing monitoring

Reframe the Challenge

We transform your standard bearings into sensors for lubrication, load and condition

or

Trusted by

Read more

about the successful collaboration with our partners

![]() trusts HCP Sense with lubrication monitoring to optimize the design of bearing lubrication without costly service life tests.

trusts HCP Sense with lubrication monitoring to optimize the design of bearing lubrication without costly service life tests.

Together with HCP-Sense integrates its sensor technology into actuators for robotic applications to generate data for even higher performance.

To investigate the suitability for condition monitoring, tests were carried out at different speed operating conditions in cooperation with

To investigate the suitability for condition monitoring, tests were carried out at different speed operating conditions in cooperation with

Series application

Your objective: Raise the monitoring of your products to a new level and maximize customer benefits.

Together, we transform your standard bearings into sensors for lubrication, load and condition. This gives you a competitive advantage over all previous monitoring systems. No additional – and therefore vulnerable – measurement technology and no redesign. Your application-specific expertise paired with our technology results in the best possible individual solution, precisely tailored to the challenges of your customers.

Measurement as a Sevice

Your objective: To expand your knowledge about your bearings, the lubricant or the surrounding process, on a test bench or in test machines

Lubrication is an important lever for optimizing the service life and energy consumption of machines. The forces at work are not only used to design the bearings, but also the entire machine. Understand bearing failures from the first crack to prevent them in the future. With our technology, we offer you a deep insight into the mechanical heart of prototypes, test machines and test benches – during operation. Our service includes project planning, installation, as well as the execution and evaluation of measurements. In addition, we offer conclusions for the optimization of your application and its operating strategy.

HCP Sense

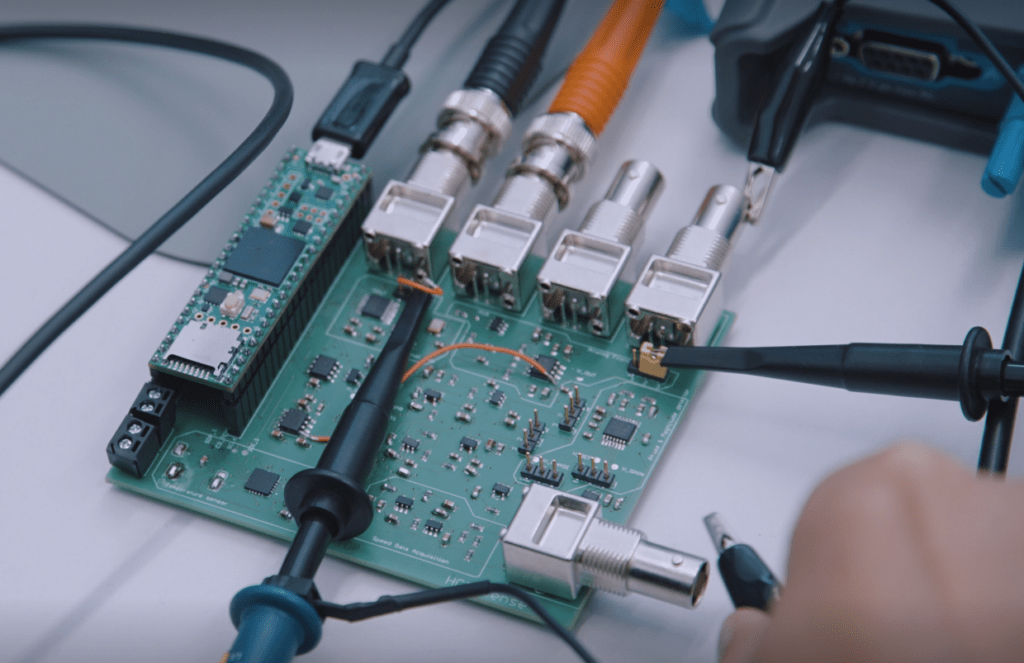

is the first manufacturer to offer an economical sensor solution for real-time collection of crucial data for process monitoring and predictive maintenance. The sensor measures and analyzes the load and the lubrication condition of rolling bearings.

Our unique technology lets your standard bearing turn into a sensor!

Our products are already being implemented for various customer applications and successful test phases have been completed.

Our sensor does not require any design changes: it is a non-invasive measurement method for measuring loads and lubrication in rolling bearings.

Cause of damage - unknown

Measurements on the test bench often do not reflect the real application. Thus, the causes of roller bearing damage often remains unknown.

High costs and reconstruction efforts

Conventional force sensors are difficult to integrate into machines and require hardware adjustments. This in turn is associated with a long project duration and high costs.

Loss of energy

20 % of global energy consumption is lost through friction. Taking Germany as an example, this equates to the electricity generated by all coal-fired power stations. One reason for this is losses due to incorrect lubrication.

Our solution

The HCP Sense sensor monitors forces, lubrication and damage in bearings by measuring electrical impedance.

Our technology works with any bearing, from small deep groove ball bearings to plain bearings and spherical roller bearings for heavy industry.

The processing and visualisation of the data is customer-specific. There is no “one size fits all” here, because every application deserves an individually optimised data analysis.

The challenges of our customers are our opportunity

Determinate the actual load and lubrication

Predict remaining lifespan

Optimisation of the operating strategy

Protect machinery and improve quality

Optimisation of the operating strategy

Reduce energy consumption while fighting climate change

Improve configuration

Reduce energy consumption while fighting climate change

Validate simulation models

Prevent bearing damage and save maintenance costs

Simple and economical:

our sensor is the best integrable solution for your system.

With HCP Sense technology you get the following advantages:

Low construction effort

Easy integration into both existing and new machinery programs

Damage prevention instead of just damage prediction

Increase availability and efficiency in all types of processes. Increase in machine and plant safety

Low engineering effort

The use of standard bearings does not change the basic design

Low complexity

Only the electrical contacting must be integrated. Basically, a thin cable with a tip is laid

High economic efficiency

Reduce costs by preventing damage and extending lubrication intervals

Increased quality

By monitoring lubrication conditions and loads

Geringer Konstruktionsaufwand

Einfache Integration in ihren bestehenden, sowie in neuen Maschinenprogrammen

Verhindern von Schaden, statt nur Vorhersagen

Steigerung der Verfügbarkeit und Effizienz in allen Arten von Prozessen. Erhöhung der Maschinen- und Anlagensicherheit

Geringer Engineering Aufwand

Durch die Verwendung von Standardlagern wird die Grundkonstruktion nicht geändert

Geringe Komplexität

Lediglich die elektrische Kontaktierung muss integriert werden. Grob gesagt, wird ein dünnes Kabel mit einer Spitze verlegt

Hohe Wirtschaftlichkeit

Kosten senken, durch das Verhindern von Schäden, und die Verlängerung der Schmierungsintervalle

Erhöhte Qualität

Durch das Monitoring von Schmierungszuständen und Belastungen