We are pleased to announce that our DISTRAL project started on 01.04.2024.

In this project, our technology will be further developed into a fully automated lubrication monitoring system using a machine learning-based diagnostic algorithm. For the user, this means a revolution in the condition monitoring of rolling bearings, with which problems can be detected long before any damage has occurred. Hence, bearing damages can be successfully prevented. For us, on the other hand, it means the expansion of our previous hardware and engineering services into a service with a digital standard product.

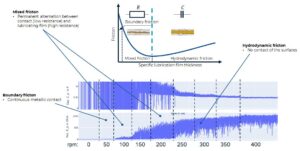

Our aim is to help our customers build more reliable and efficient machines. The technology is a new type of sensor system for monitoring rolling bearings. It uses the electrical properties of the bearing itself, more precisely the electrical impedance. It depends on the lubrication condition and the force of a rolling bearing. Thus, no complex sensor technology is required to monitor the lubrication.

Figure 1. The HCP Sense product consists of mechanical and electrical hardware an

Figure 2. Lubrication-induced bearing damage (gray spotting). Image source: RWTH Aachen

The demand of our customers for our solutions is high. This is demonstrated not only by awards (including the winner of the special prize in the VDMA start-up competition and winner of the Hessian Founder Award 2022), but above all by the large number of ongoing development projects with a large number of customers – from a medium-sized company in Hesse such as Johannes Hübner GmbH to global corporations such as Robert Bosch GmbH.

Our innovative technology enables a radical paradigm shift in the monitoring of rolling bearings. Conventional monitoring technologies measure temperature and vibration and can only detect damage once it has already occurred. Hence, no time for a maintenance is left. HCP Sense solution, on the other hand, can detect the most important cause of damage – lubrication problems – and thus successfully prevent damage. before it occurs. Thus, it offers immense, almost disruptive, potential to make machines more efficient, sustainable and reliable.

The DISTRAL project will enable the current diagnostic model to really unlock this potential benefit. In the project, the product will be expanded to include a machine learning-based diagnostic component, at the heart of which is a completely newly developed diagnostic algorithm. The project also includes the infrastructure required for a digital product in the cloud and the measurement hardware. This raises the diagnostic function to a new level and enables a digital business model with a direct connection to the customer and corresponding additional benefits. The funding from DISTRAL enables HCP Sense to take this development step and exploit the potential benefits of its technology.